Dear customers online sales have stopped for a week while we await new stock. Read about the production process | Free Shipping for all orders over £50

Pottery firing temperatures for earthenware

Earthenware is a type of pottery fired at low temperatures, often between 1,080°F (580°C) and 1,200°F (650°C). The lower temperature range is known as “bisque firing” and is commonly used to harden and dry the clay, while the higher temperature range is known as “glaze firing” and is used to fuse the glaze to the surface of the pottery.

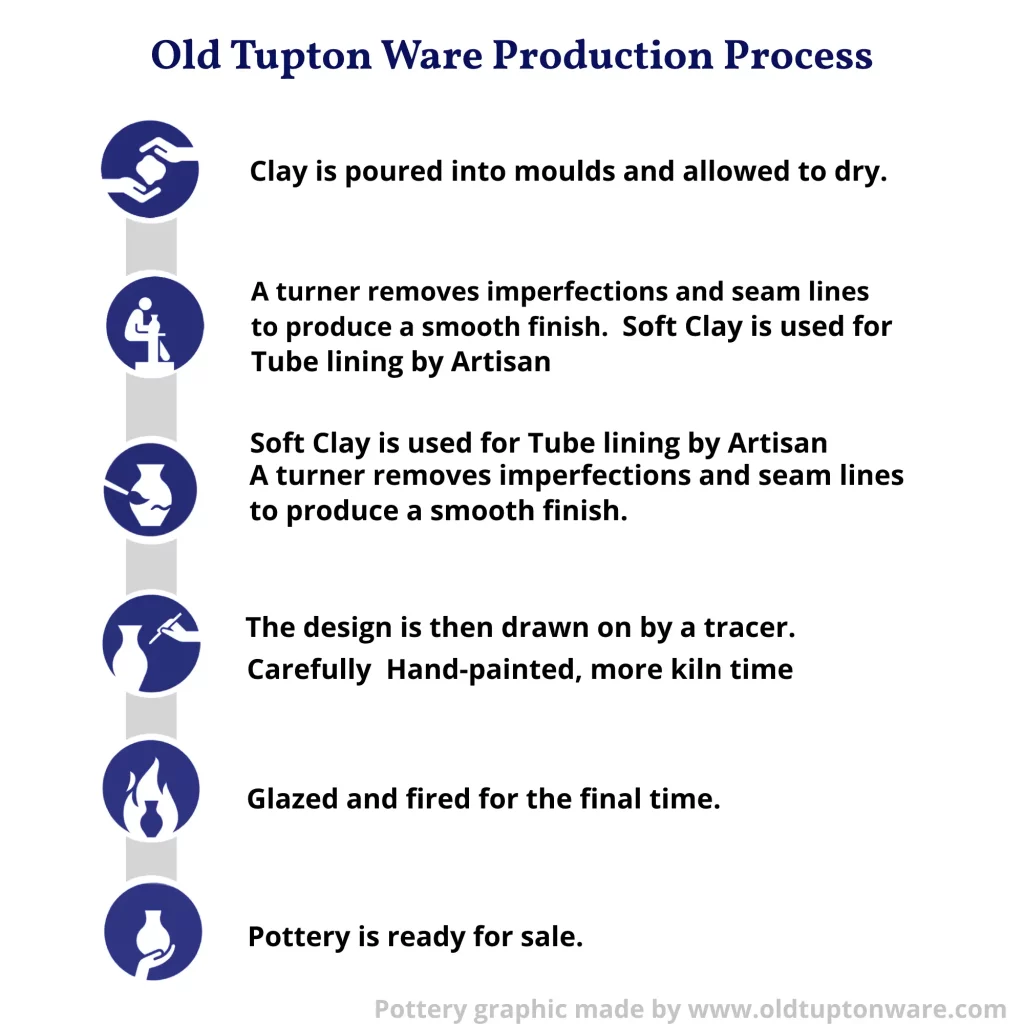

Old Tupton Ware pottery creation process from start to finish

The clay body matures and becomes robust enough to resist the glaze firing process during the bisque firing process. The glaze is a liquid coating that is put on the surface of the pottery. It is made of glass, feldspar, and silica and is fused to the surface at a higher temperature to make a hard, shiny surface.

Earthenware firing temperature varies based on the type of clay and glaze used, as well as the desired effect. While certain earthenware pottery may be fired at lower temperatures, approximately 1,080°F (580°C), others may be fired at higher temperatures, around 1,200°F (650°C). To generate distinctive effects and patterns in their pieces, some potters may even fire their pottery between 1,260°F and 1,320°F (688°C and 715°C).

httpv://www.youtube.com/watch?v=LjsKTEQX3lg

It is important to note that the firing process has a significant impact on the ultimate output of the pottery piece; it influences the strength and durability of the pottery, the colour and texture of the surface, and the overall beauty of the item. “To attain the desired results, potters must be informed and competent in the firing process.” Old Tupton Ware